Research + Design Advanced Studio

Try It Yourself!

Learn more ways in which to make your own bio-materials out of household byproducts from home.

Corn starch can be used to replace the cement in concrete. This recipe is simple and can be made in the microwave. Pro tip: You can replace the sand aggregate with soil.

The banana peels can be used to make composite leather by drying the pulp out and the fibers can be used for textile weaving.

Orange peels can be combined with household items to create and edible material suitable for packaging and other objects.

Apple pomace is a very bioavailble byproduct, particularily in New York State. The Adam Sheet is a tensile bioplastic that is durable and waterproof.

Wheat straw, though not in every kitchen, can be combined with glue and paper to make a strong composite similar to plywood.

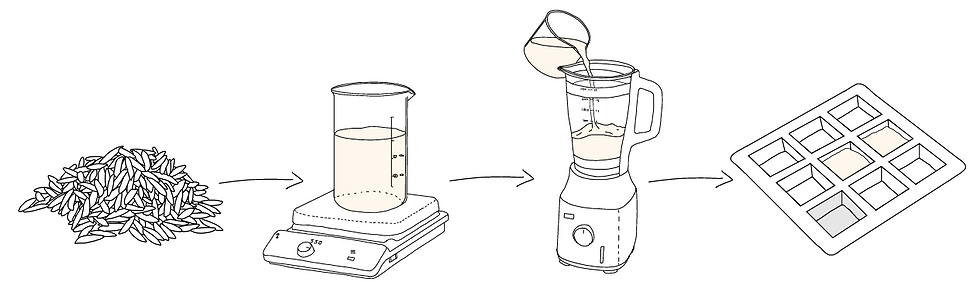

Rice husks are a common surplus in the agricultural industry. Turns out, rice husk ash can be used to replace cement.

Palm fibers can be combined and heat pressed together to create a packaging product that will decompose within 90 days.

Coffee has been prooven as an incredible substitute to sand when making concrete. It is stronger and a natural surplus byproduct. This can be done at home!

Sunflower seed shells are a common byproduct from everyday snacking. They can be used directly as compost or can be transformed into biomaterials.

Excess eucalyptus bark can be processed into blocks that are wonderful thermal and sound insulators.